SK-150-3000-7.8-FJ-E

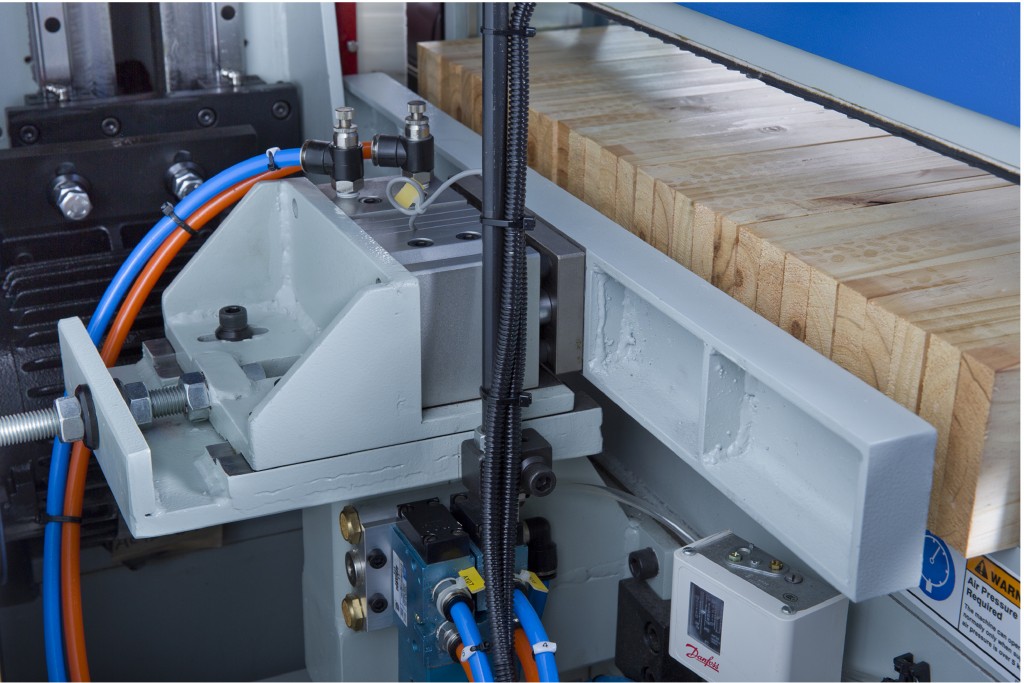

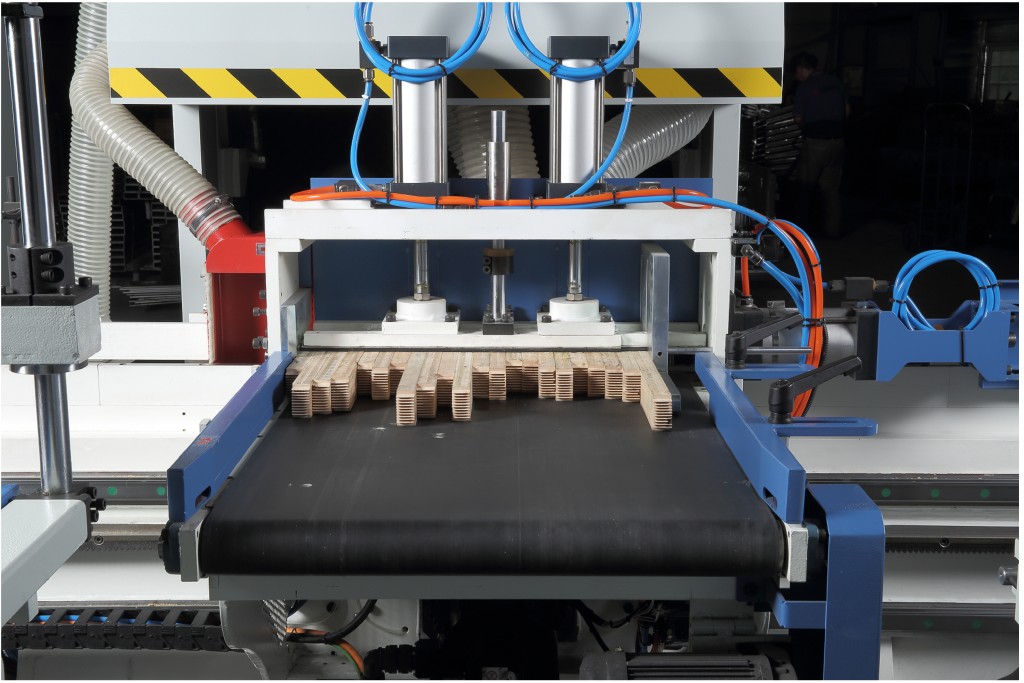

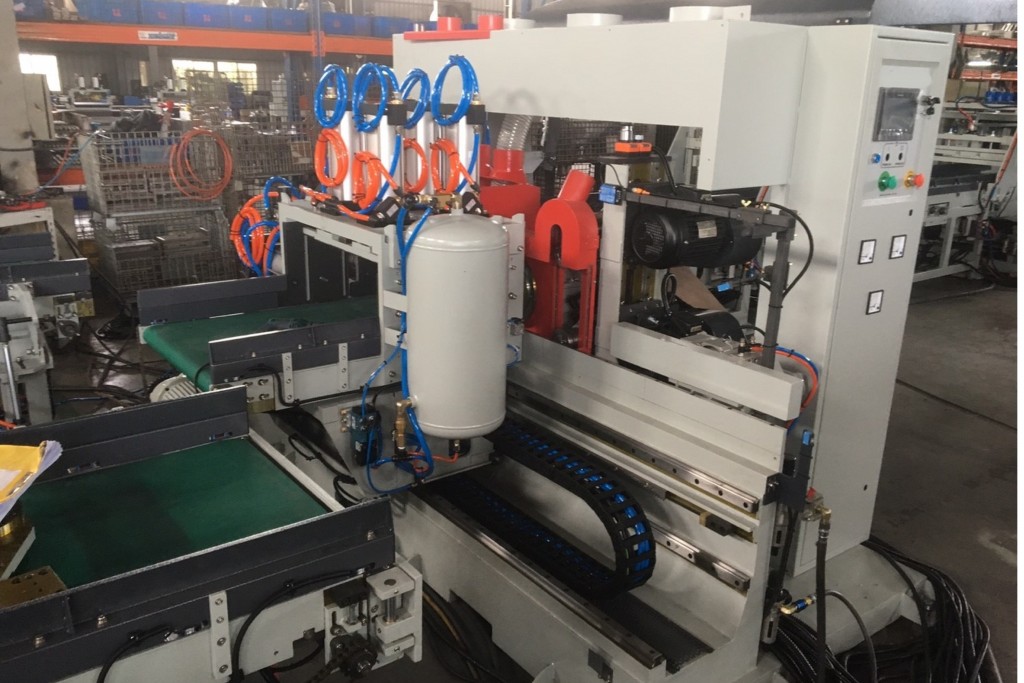

Heavy Duty Inverter Finger Jointer System - With Auto Storing-Feeding Conveyor

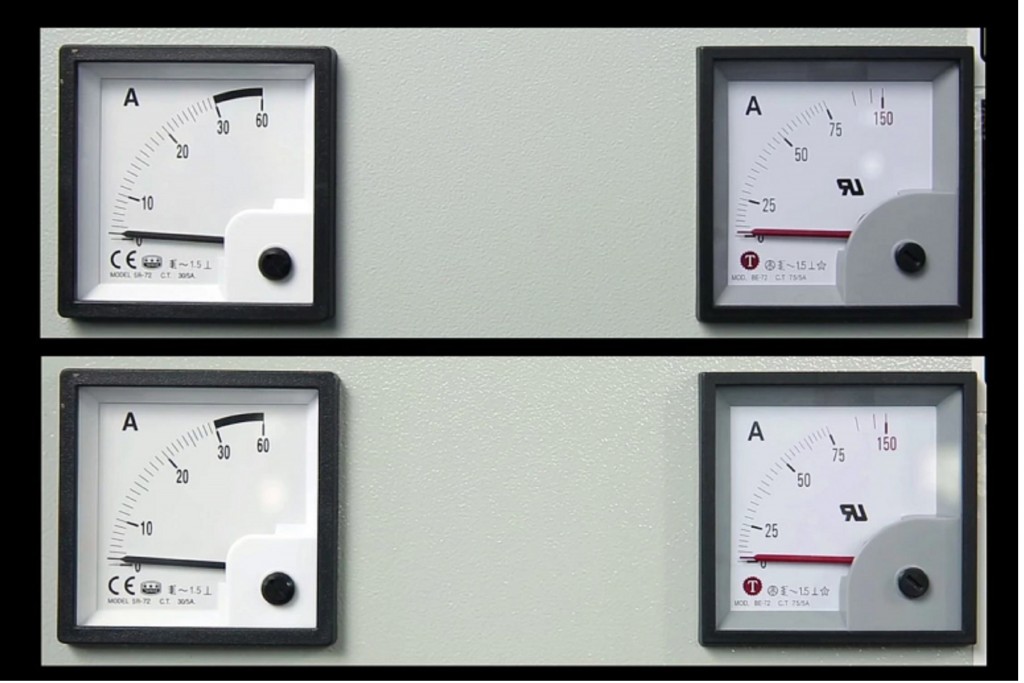

Inverter drive system. This series is designed for some customers with lower height processing size, but need higher capacities. Working speed is faster 30% than hydraulic type.

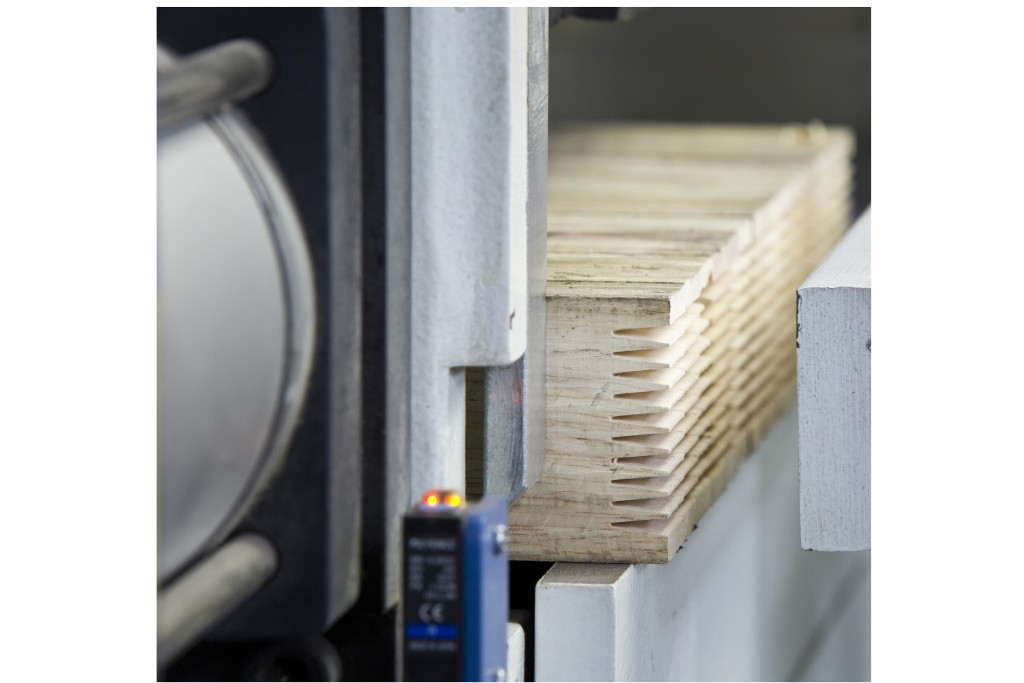

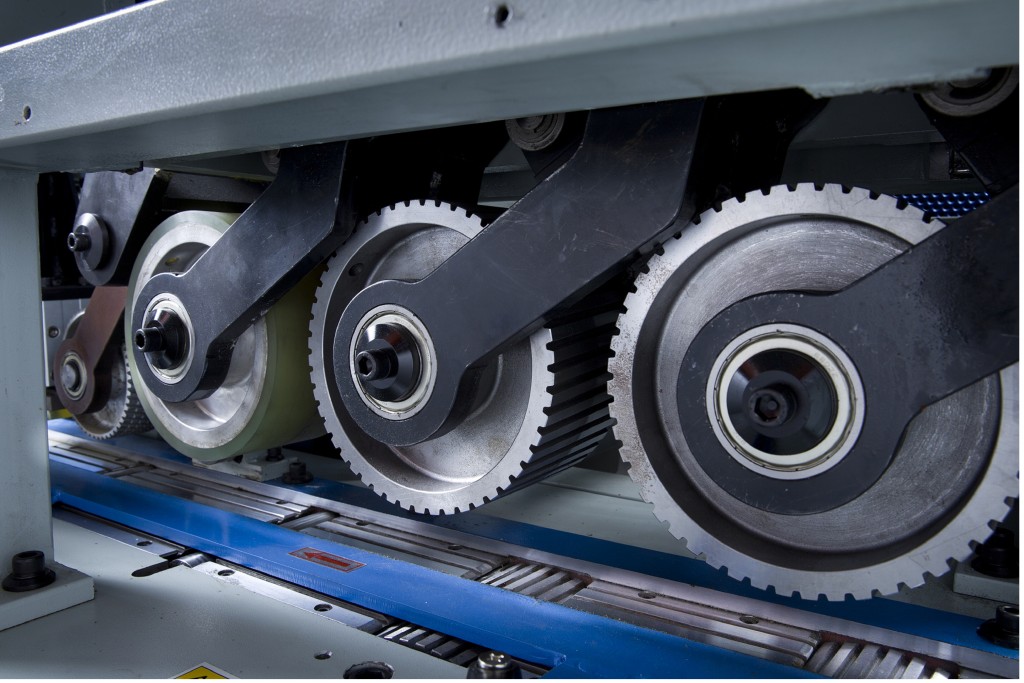

Prefect Joint

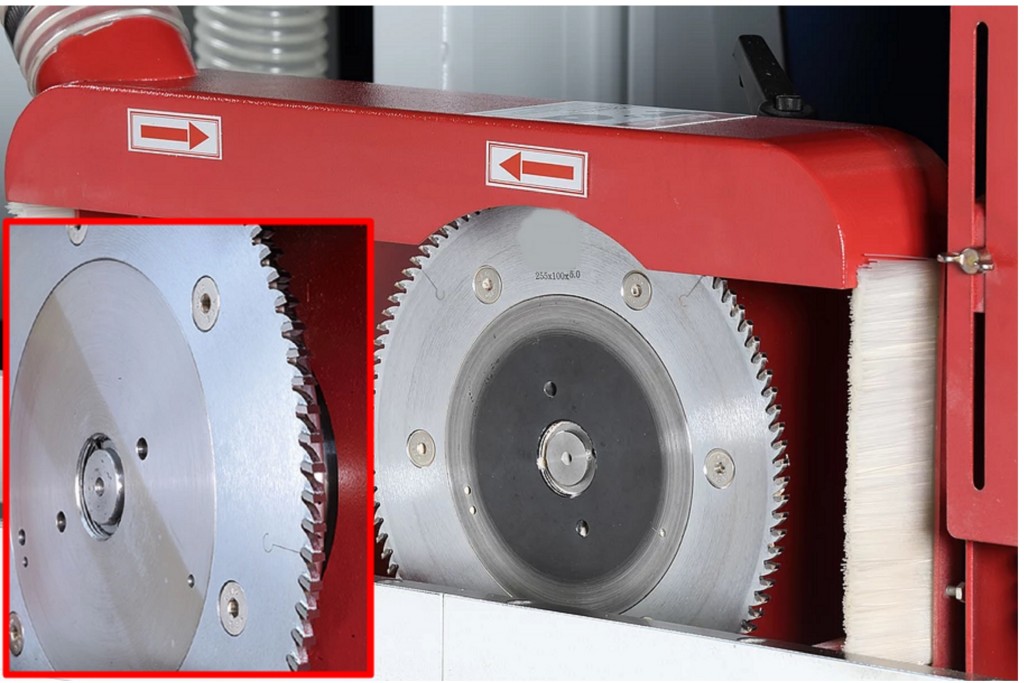

Finger joint system it seems an easy working system. We must focus on the design of every small detail on the machine, in order to get the perfect finger joint finished products.