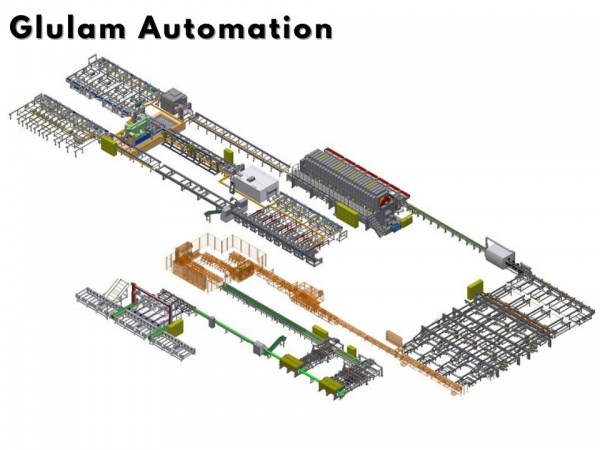

Glulam Automation

1. Robot arm use vacuum stacker for stacking strips removal. The computer scan the QR code on timber pack and confirm if the size of timber is correct. The vacuum stacker can also stack the timber with coarse surface and it is dirt resistant.

2. Ergonomic working platform for operator to mark line on timber and feed into optimizing cut off saw.

3. Optimizing cut off saw cut the timber to the specified length and classify the timber.

4. Auto paddling system between optimizing cut off saw and finger jointer, distributes the wood pieces with sensor recognition depend on customized size range.

5. Auto finger joint line for infeed length 3M x width 250mm x thickness 50mm and outfeed length 13M materials. With color spray printer for identify the timber.

6. Curing storage (2 layers) with lug chains

7. 100m per minute high speed moulder

8. Automatic roller + chain infeed conveyor with turning device.

9. Automatic rotary press for max. 13M long x 1200mm wide x 250mm height of wooden beam.

10. Double surface planer for 1300mm wide x 250mm height material after rotary press.

11. Horizontal band resaw for cutting the timber into specified thickness.

12. Lifting mechanism for separating up and down timber and feeding into beam planer.

13. Beam planer for 1300mm wide x 250mm height wooden post or beam.

14. Beam Saw for cutting 13M long beam into customized length. Cutting width x height 1300x250mm

Facts

1. Factory Size: Length x Width 120M x 70M = 8400m2

2. Infeed size: Up to 6M long x 250mm width x 50mm thickness

3. Up to 13m x 1200mm x 250mm beam size

4. Up to 30m3/shift 8 hour for glulam beams

5. Plant layout can be customized according to factory size.